Airports can be considered one of the most complicated logistic settings in the world where each second and square meter may be a matter of life and death. The improper gear in the ramp, an oversized tug, underpowered forklift, or slow belt loader can make aircraft turnaround slow and increase safety hazards. Airport ground handling equipment in the high-stress environment of ground operations must be ideally adapted to aircraft type, size of loads, and ramp configuration. In this blog, the author describes the efficacy of right-sizing GSE (Ground Support Equipment) as the way that enhances efficiency, cost saving, and safer, quicker turnarounds.

What Is Airport Ground Handling Equipment (GSE)?

Airport ground handling equipment are specially equipped vehicles and equipment that are used in assisting aircraft on the ground. This involves loading, unloading, towing, fueling and cargo moving equipment. Examples that are common are baggage tugs, belt loaders, container handlers, and forklifts that transfer cargo or unit load devices (ULDs) between the aircraft and the warehouse.

In the case of airports, airlines as well as logistics providers, efficiency and safety have to be balanced by choosing the appropriate combination of ground handling equipment. Too powerful or too large machines may cause harm to aircraft and the opposite may cause unnecessary delays that prove to be expensive.

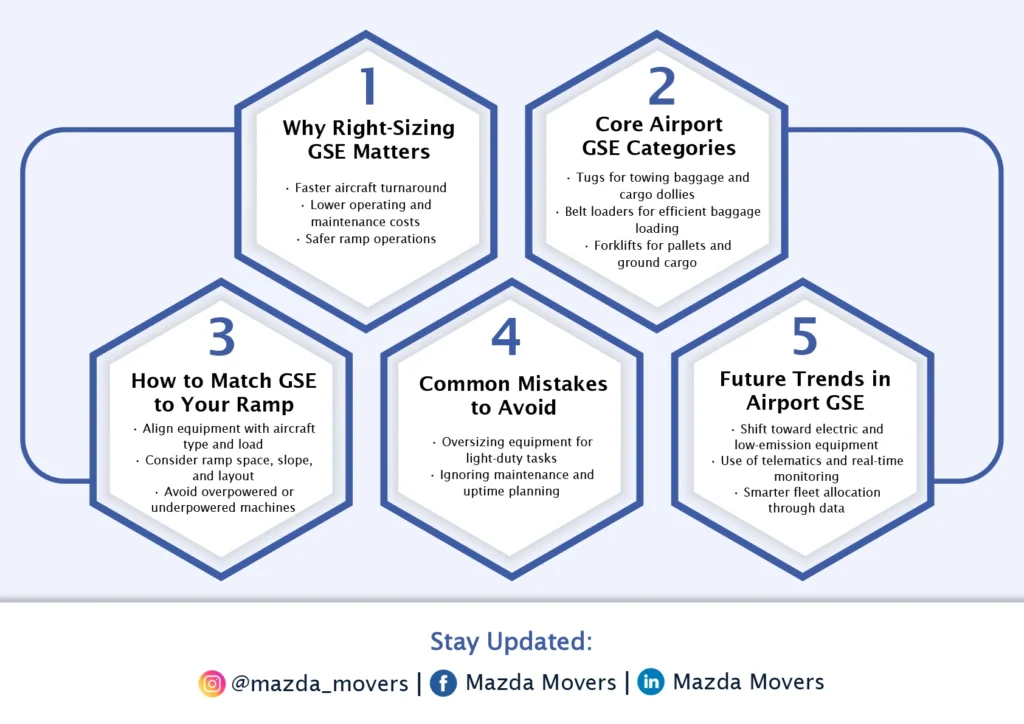

What Is The Reasons Why Right-Sizing Is Important to the Operation of an Airport?

Selecting the appropriate size and kind of equipment is not only convenient but it is also about ensuring maximum productivity and reduction of time. As passenger numbers grow and the schedules are tightened, there is continuous pressure on the airports to optimize the available resources.

- Improved Turnaround Time: When fitted with forklifts and tugs that most suitably match aircraft weight and load size, they minimize the time that can be idle between flights and enhance the efficiency of the gates.

- Reduced Operating Costs: Large tugs or forklifts also burn more fuel and need more servicing and wear out tires and brakes. Through right-sizing, leaner and cost-effective ramp operations are guaranteed.

- Enhanced Safety: The right GSE minimizes accidents, enhances stability in handling, and preserves sensitive cargo, aircraft fuselage, and crew during rampage.

- Sustainability and Efficiency: Electric forklifts and belt loaders of the new generations are emission-free, which is aligned with green airport programs and reduces operational noise.

What Is The Basic Equipment and Roles of Operation?

Each ground handling equipment has its purpose and load range.

- Tugs and Tractors:

Tugs move baggage carts, dollies, and cargo containers. The selection of the tug is determined by the sum of the towing weight and the ramp slope. In the case of narrow-body aircraft, small capacity electric tugs are enough, and in the case of wide-body aircrafts, one should use diesel or hybrid tugs. - Belt Loaders:

Belt loaders are essential in loading baggage into aircrafts. The current models have adjustable booms, non-slip coatings, and accurate hydraulic adjustments to minimize handling damages and enhance speed. - Forklift Trucks:

Forklifts are very important in ferrying pallets, containers, and ground cargo. Electric forklifts are used within the facility close to the terminals, whereas the dominance of the diesel forklift is in the ramp and warehouse operation. The collaboration with trusted forklift truck dealers will allow obtaining safe and durable machines that fit the aviation logistics. - Container Handlers:

These are sturdy machines that accommodate bulky ULDs, cargo pallets, and containers. The correct container handler dealer will be able to advise about lift height, lift capacity, and maneuverability depending on your terminal plan.

How to Right-Size GSE to Ramp Operations

An appropriate choice of airport ground handling equipment requires a fine balance between capacity, mobility, and operational demand. The steps normally taken are:

- Assessing Aircraft Mix: Calibrate GSE specifications to the most common types of aircrafts that have been serviced such as ATRs to A350s in regard to their cargo capacity and their hold height.

- Evaluating Load Profiles: Determine the weight and frequency of cargo or baggage per flight to select forklifts and tugs which can manage peak loads with no idle capacity.

- Considering Terrain and Layout: The decision on tugs and loaders depends on ramp gradient, turning radius, and parking positions. Small machines provide maneuverability in narrow areas.

- Including Maintenance and Uptime: Using the services of providers who offer forklift renting and annual maintenance contracts will provide stable reliability with no significant investments.

Technical assessment and operational measurements allow airports to optimize fleet use and improve safety rates.

What Is The Biggest Mistakes and Ways to Avoid Them

The most frequent error in GSE procurement is that of overestimating load requirements. The acquisition of oversized forklifts or high-torque tugs for light duties raises fuel consumption and maintenance costs. Underpowered units, on the other hand, may lead to overloading and early failure of components.

The second issue is the fact that the importance of training operators and equipment maintenance schedules is overlooked. Cooperation with established forklift service companies and authorized dealers guarantees long-term reliability, appropriate calibration, and the availability of OEM forklift spare parts.

What Is The Future Airport GSE Trends and Innovations

Global airports are shifting to the electrification and automation of ramp operations. Forklift trucks and autonomous tugs are becoming more efficient and minimizing emissions. Telematics are real-time tools that monitor the use of equipment, whereabouts, and performance in an effort to optimize fleet deployment.

Container yards and terminals are also using AI-controlled solutions to predict the movement of cargo and allocate equipment to it in real time. These technologies are transforming how container handling services and ramp logistics services are handled in key hubs.

How To Maximise Your Airport Business

No matter what you are handling—ground operations or logistics support—the right-sizing of your fleet of airport ground handling equipment will make workflows much easier and ramp activity safer. Consult professional forklift truck dealers and container handler dealers that are aware of your operating environment and can give custom advice to your fleet size, aircraft mix, and turnaround objectives.

To address short-term requirements, we suggest the option of forklift on rent or forklift rental service that includes flexibility and professional maintenance services.

Conclusion

Finding the appropriate airport ground handling equipment is not just a procurement choice, but a forward-thinking and cautious investment in security, productivity, and sustainability. Starting with forklifts to belt loaders and tugs, each of the devices contributes to shortening turnaround time and maximizing the overall performance.

Airports can future-proof their ramps and ensure that all flights remain on schedule efficiently and safely by collaborating with trusted service providers or by outpacing emerging technologies.

Stay connected with Mazada Movers — follow us on LinkedIn, Instagram, Facebook for updates, insights, and moving tips

FAQs

- What is the initial anonymity of GSE in airports?

GSE is an abbreviation that implies Ground Support Equipment, and it comprises all the machinery necessary in maintenance of aircraft on the ground. - What is the value of right-sizing GSE?

It will make sure that the right equipment is applied to the right operation, which enhances safety, efficiency, and maintenance costs. - Is it possible to rent GSE on short-term projects?

Yes, a substantial number of airports hire forklifts or forklift on rent services on a seasonal or temporary basis. - What is the recent trend in the GSE of the airports?

The most current trends of sustainable, data-driven ramp operations are electrification and telematics-based tracking